Description

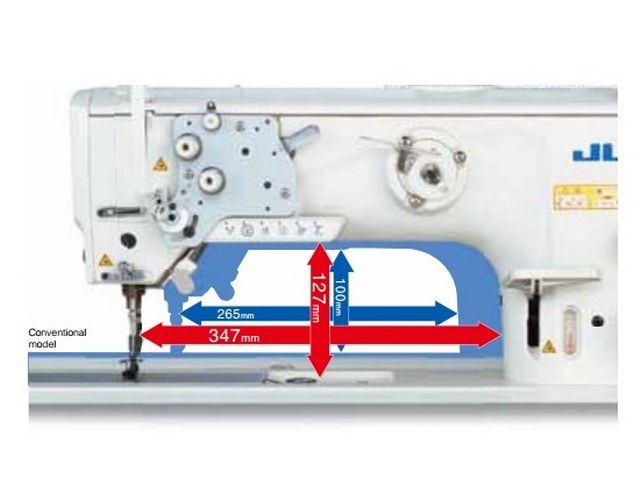

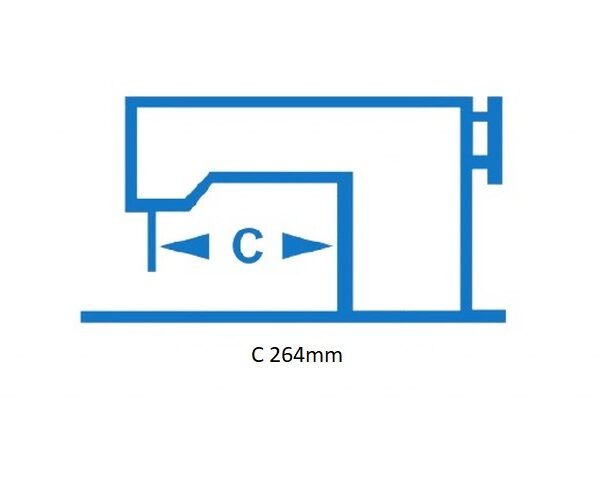

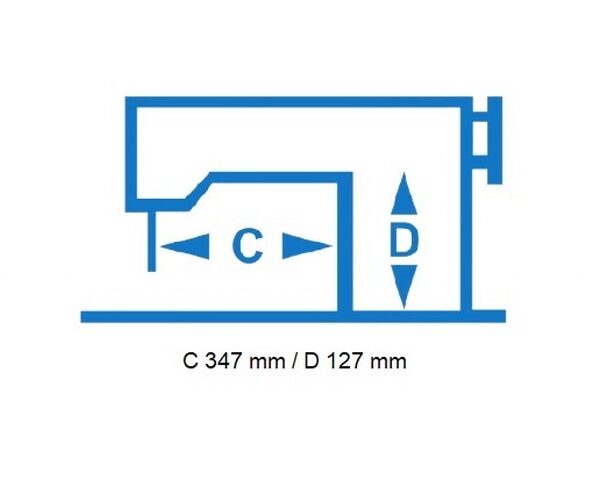

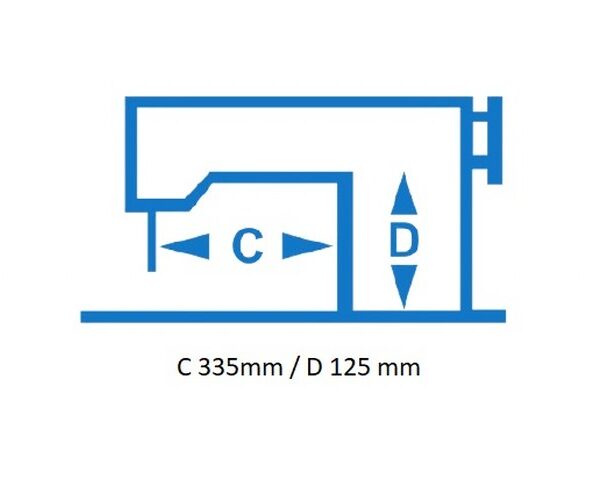

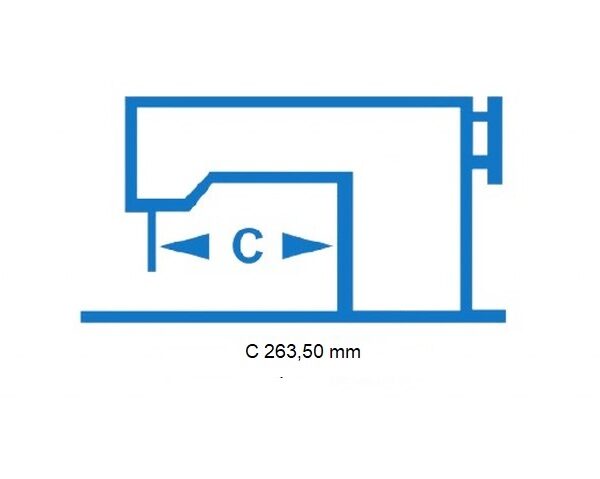

The LU-2800 Series is a unison-feed, lockstitch machine with a vertical-axis large hook which is provided with substantially improved functions and performance, the long distance 347mm from the machine arm to the needle contributes to increases productivity

The JUKI LU-2810-7 is a single needle walking foot machine with automatic functions for sewing medium to heavy weight leather, canvas, vinyl and thick synthetic materials for upholstering automotive, marine and aviation seats, furniture upholstery, leather bags, belts, wallets and other similar articles.

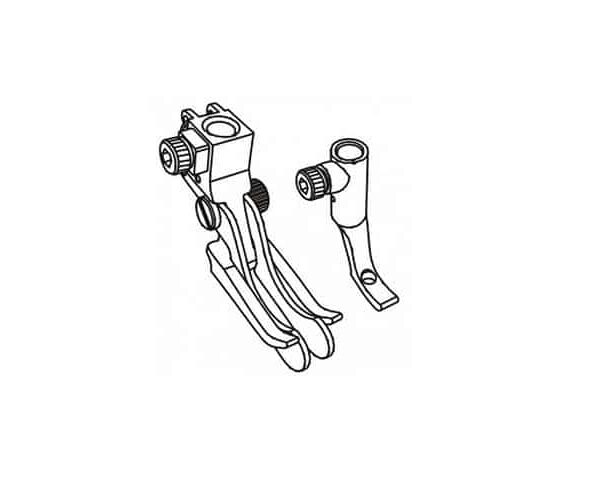

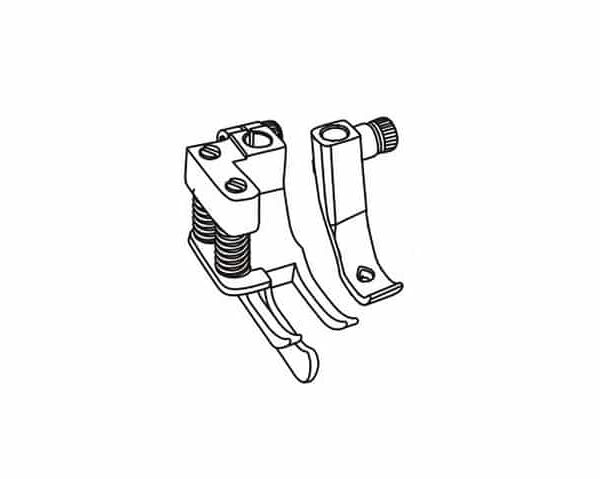

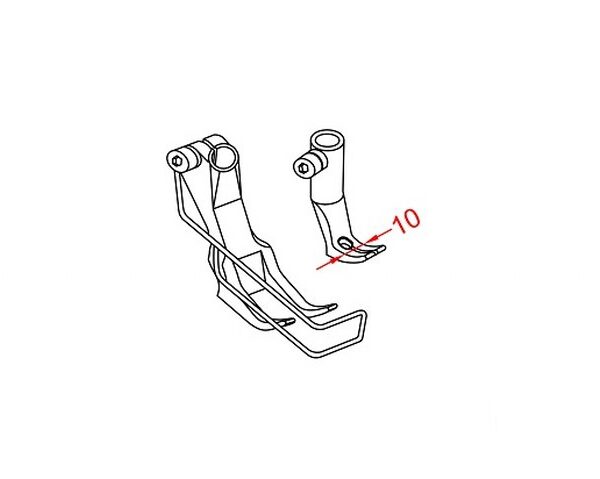

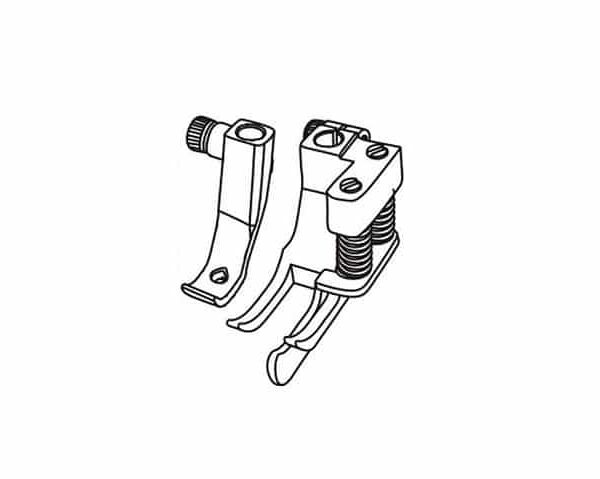

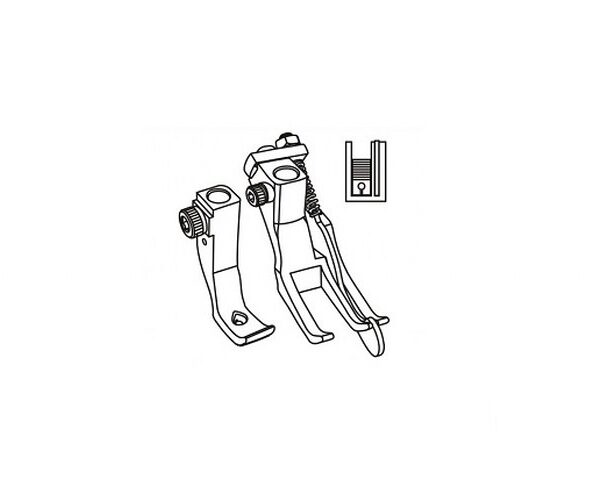

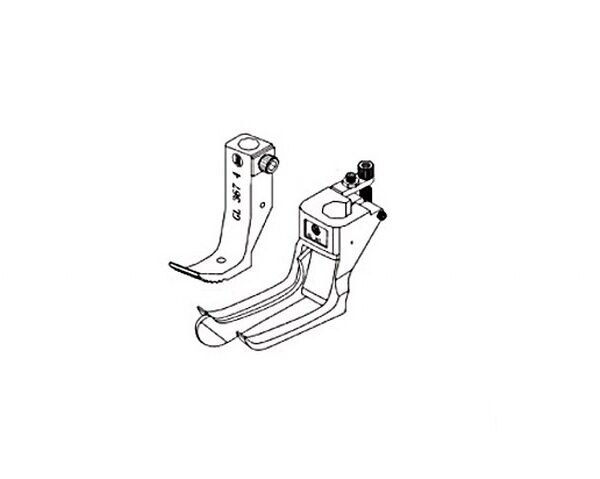

With its larger needlebar stroke, higher presser foot lift, and newly adopted double-tension mechanism, the machine offers excellent sewing capabilities

The machine’s rectangular feeding motion promises the consistent feeding of materials of all thickness without stitch gathering.

The oil dropped from the hook and its surrounding sections into the under-cover is filtered to remove dirt and dust and is then returned to the oil tank.

This method saves the effort of oiling and reduces oil consumption.

The remaining oil quantity indicator is provided on the front face of the machine head. Lubrication can be carried out without tilting the machine head.

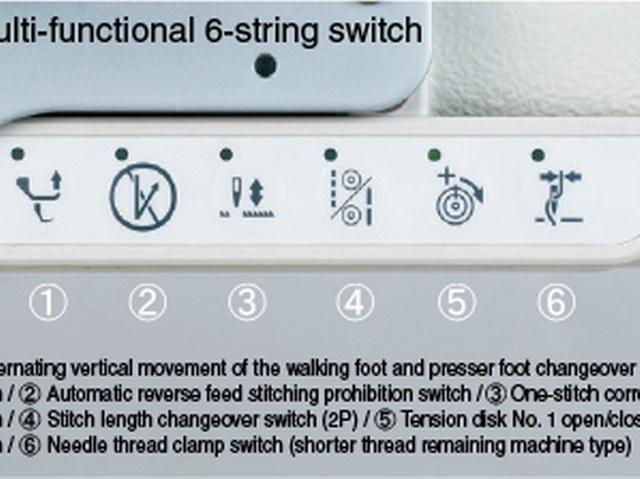

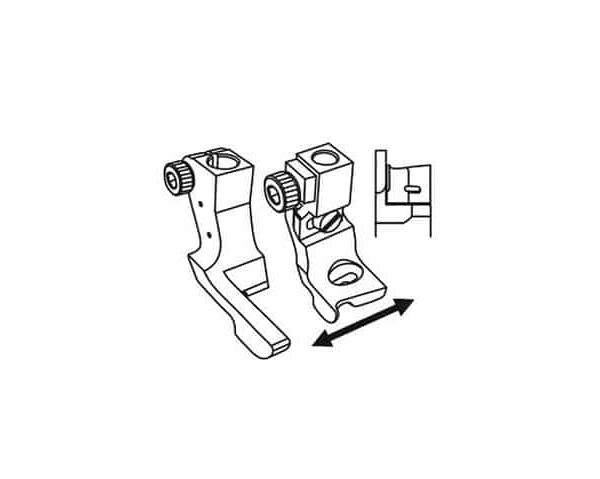

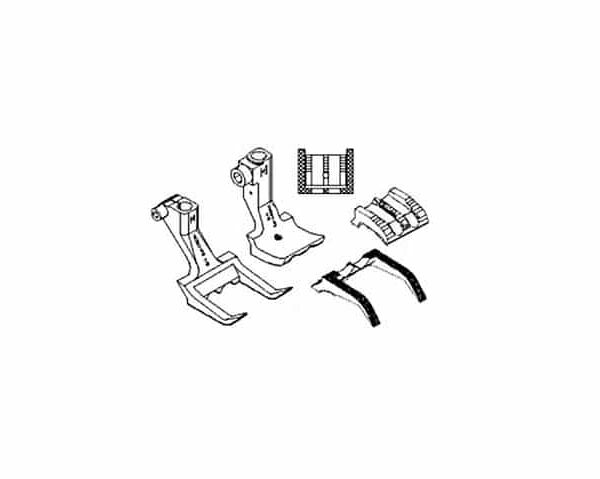

Built-in multi-functional switch allows change alternating vertical movement of the walking foot and the presser foot and changeover of the stitch length

The sewing machine with a thread trimmer is provided as standard with a 2-pitch dial.

Adjustment of the eccentricity of the feed driving cam has been enabled. As a result, the sewing machine is able to perform sewing with the feed that is best-suited to the material and thread used.

The sewing machine provided with a thread trimmer has adopted a high-torque direct-drive motor which is suitable for heavy-weight materials. As a result, the sewing machine is excellent at its responsiveness and ensures increased penetration into the material even when sewing multi-layered parts.

The direct-drive motor system has been adopted by all of the sewing machines with a thread trimmer. As a result, the sewing machine starts up swiftly and promises increased stop accuracy, thereby demonstrating improved responsiveness.

In addition, the machine is no longer provided with a V-belt. This means that the adoption of the direct-drive motor is also effective in the elimination of belt shavings. Power is directly transmitted from the motor to the sewing machine, thereby contributing to reduced power consumption. (This sewing machine reduces power consumption by 37% as compared with the conventional models.) Adoption of a direct-driven main shaft and a revamping of mechanism design contribute to remarkably reduced noise. Noise has been reduced by 3.5dB as compared with the conventional model.

1 YEARS WARRANTY PREMIUM

JUKI LU2810-7 industrial machines have 1-year, full warranty.

STAND HD PREMIUM – steel, stable and durable stand for heavy machines with height adjustment

JK SERVO PREMIUM – energy-saving, single-phase 220-240 V AC Servo motor. Works only when the machine is sewing (no idling running). Even though its power exceed previously used electronic and standard clutch motors

Technical specification for download: Click here

| 1-needle lockstitch for materials | medium and heavy |

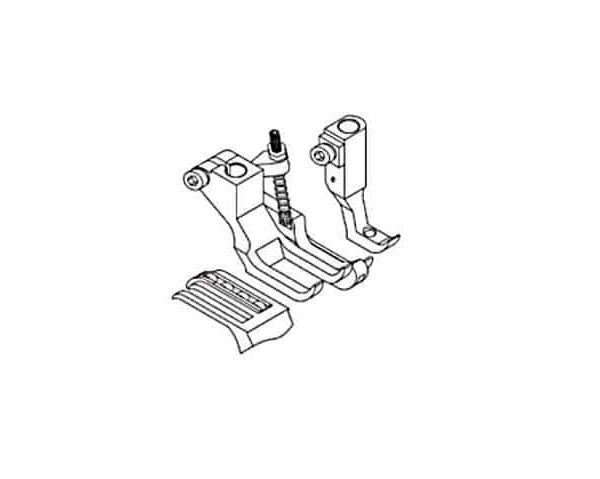

| Type of feed | unison (walking foot) |

| Automatic thread trimming | yes |

| Automatic needle positioning | yes |

| Automatic foot lifter | yes |

| Automatic bartacking | yes |

| Wiper | no |

| Stitch compensation button | yes |

| Type of lubrication | central circuit, semi-dry |

| Side trimmer | no |

| LED lighting of working field | no |

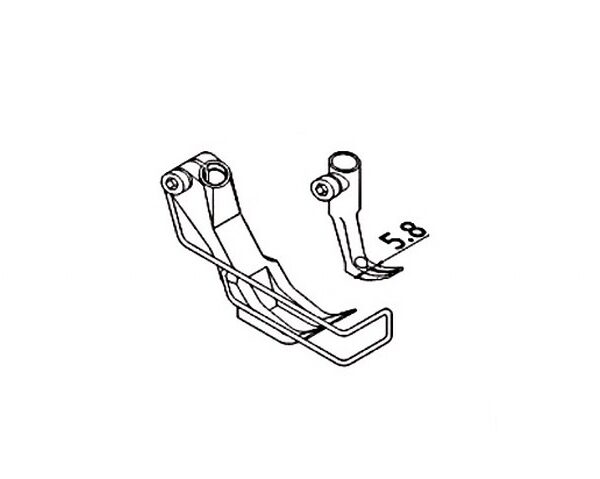

| Max. stitch length | 12.0 mm |

| Presser foot lift height | 20 mm |

| Max. sewing speed | 3000 s.p.m. |

| Built-in AC Servo motor | yes |

| Needle system | 135X17 |

| Table top | standard 105 x 50 cm |

| Warranty period | 12 months |

| Kit | complete set |