Description

New and powerful machine for sewing tubular materials

The MO-6900C with a small-in-diameter cylinder bed, is capable of runstitching or blind-hemming tubular materials, such as sleeve cuffs, with ease.

The operator can carry out sewing of the tubular material while turning it downward. This promises improved workability and contributes to dramatically increased productivity.

The MO-6900C Series is a new and powerful overlock machine that has been developed to offer increased reliability and ease-of-use, while upgrading seam quality at higher sewing speeds.

It responds to a wider range of materials and processes. With the operating noise having been reduced and increased durability ensured, the cost-effective MO-6900C Series is a leading machine in the new era.

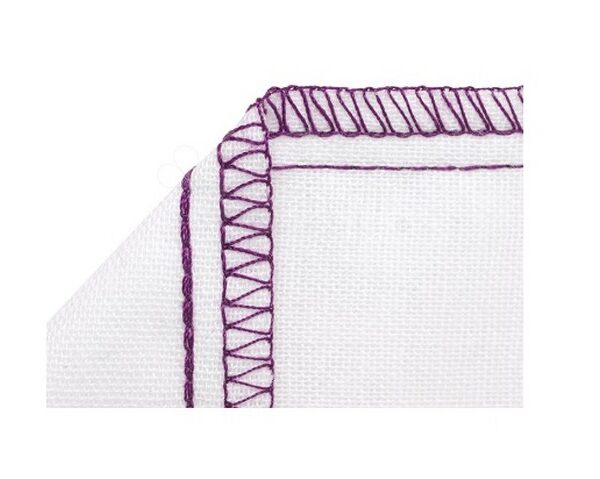

The machine ensures both beautiful and upgraded seam quality at higher speeds. Since the machine comes with a needle-thread take-up mechanism as well as a looper thread take-up mechanism, to offer upgraded responsiveness from light- to heavy-weight materials with a lower applied tension, it achieves well-tensed soft-feeling seams that flexibly correspond to the elasticity of the material at the maximum sewing speed of 8,000 sti/min.

To offer improved sewing capabilities as well as to prevent stitching misshapes, the machine is equipped as standard with the needle thread heat remover and needle cooler.

The machine has been developed with the intention of providing an extended service life. The machine incorporates various mechanisms as standard, such as a differential-feed micro-adjustment mechanism and an external adjustment mechanism for adjusting the feed dog inclination as well as increasing the differential feed ratio, which can be easily adjusted to finish seams that perfectly match the material to be used. Comfortable operation is all but guaranteed, by a wider area around the needle entry, the adoption as standard of a micro-lifter feature that offers improved responsiveness to materials and provides the operator with upgraded operability, and by the reduction ofoperating noise and vibration, which has been achieved by designing an optimally balanced machine.

Technical specification:

– for sewing light to medium fabrics

– maximum sewing speed 8.000 s.p.m.

– differential feed

– direct drive type needle bar

– total seam width 4 mm

– stitch length up to 4 mm

– energy-saving, AC SERVO MOTOR, voltage 220-240V

– 70% energy-saving

– quiet work, minimized vibrations

– central lubrication system

– needle system B-27

1 YEAR WARRANTY

One year full warranty.

Top monting on table

STAND – steel, stable and durable universal stand with height adjustment.

TABLE – the highest quality table top made of moisture resistant birch plywood which perfectly damps vibrations. Table top surface is coated with a special laminate resistant to impact, abrasion and splinters. Sides protected by wooden slats. Table tops do not contains harmful ingredients.

Enjoy the silence, save energy.

| Number of threads: | 3 |

| Overlock machine for application: | universal |

| Overlock machine for materials: | light to medium |

| Overedging width: | 4 mm |

| Total seam width: | 4 mm |

| LED lighting of working field: | no |

| Presser foot lift height: | 7 mm |

| Max. sewing speed: | 8,000 s.p.m. |

| AC Servo motor: | yes |

| Needle system: | B-27 |

| Warranty period: | 12 months |