Description

High-Speed Sewing System with Direct Drive and Automatic Thread Trimmer

JUKI’s commitment to “seam quality” is entering a new era with its next-generation sewing system, driven by digitalization. Until recently, sewing machines were adjusted manually based on operator intuition and experience. Now, with JUKI’s digital sewing system DDL-9000C, machine settings are fully digitized, allowing precise reproduction of settings to match the materials being sewn.

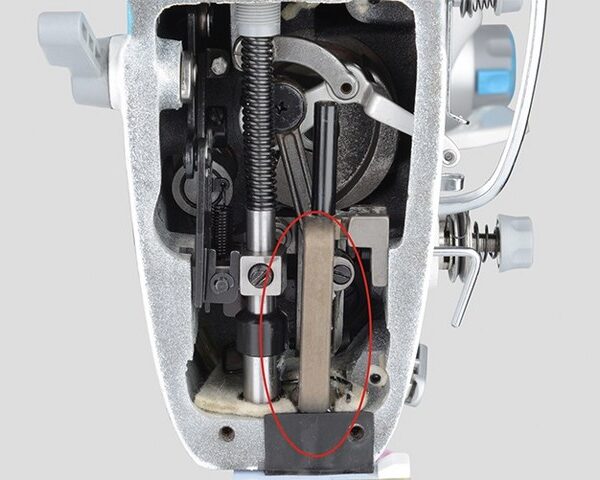

Vertically and Horizontally Controlled Digital Feed Mechanism

Thanks to the world’s first digital vertical drive mechanism, the presser foot height can be easily adjusted according to the fabric being sewn, improving seam quality. This mechanism also allows thread trimming with the feed dog lowered when the short thread trimming function is enabled.

As a result, the gap between the throat plate and the material is eliminated, stabilizing the thread length after trimming. When the needle is raised, the feed dog remains lowered, making it easier to place and remove the material, preventing fabric damage.

Selectable Feeding Options

With the digitalized mechanism, feed settings such as the feed position can be easily adjusted from the control panel to suit the material.

Digital Functions for Superior Seam Quality

Ⅰ. Active Needle Thread Tension – Needle thread tension is digitally controlled. Parameters can be set on the control panel and stored in memory, reducing setup time when switching products. This is particularly useful for complex materials with varying textures.

Ⅱ. Active Presser Foot Pressure – The pressure is digitally controlled. In automatic mode, the system adjusts the pressure according to changes in material thickness, while in manual mode, operators can adjust it via a displey switch.

Ⅲ. Needle Thread Clamp – This device clamps the needle thread and pulls it under the material at the start of sewing, reducing the size of thread loops on the wrong side and allowing the use of various gauge components.

Sewing Machine Management via IoT ( option )

Machine settings can be transferred wirelessly to an Android tablet, enabling quick verification of unique settings and machine status. The machine also features a USB port for data management and software updates via a USB flash drive.

LED Lighting on DDL-9000C

The LED light illuminates the needle entry area from both sides, making sewing easier for operators. The brightness is adjustable in five levels and can serve as an auxiliary light.

Machine is serial equipped with automatic functions:

– needle positioning

– thread trimmer

– automatic presser foot

– reverse feeding with programmed size of the initial and final bartack

– possibility of programming sewing sections

– controller of initial stitch

– max. sewing speed 5000 s.p.m.

– bottom feed

– max. stitch length 5 mm

– advanced programming functions

| 1-needle lockstitch for materials | light and medium |

| Type of feed | bottom |

| Automatic thread trimming | yes |

| Automatic needle positioning | yes |

| Automatic foot lifter | yes |

| Automatic bartacking | yes |

| Wiper | no |

| Stitch compensation button | yes |

| Type of lubrication | closed “semi-dry” circuit |

| Side trimmer | no |

| LED lighting of working field | yes |

| Max. stitch length | 5.0 mm |

| Presser foot lift height | 13 mm |

| Max. sewing speed | 5000 s.p.m. |

| Built-in AC Servo motor | yes |

| Needle system | 135X5 |

| Table top | standard 105 x 50 cm |

| Warranty period | 12 months |

| Kit | complete set |