Description

JUKI MF-7223D-U10B56/UT45 SC921BN-CP18B

Semi-dry-head, Small-cylinder-bed, Top and Bottom Coverstitch Machine

The sewing machine is applicable to the sewing of sleeve cuffs, necklines and children’s wear.

DRY-HEAD TECHNOLOGY

The frame no longer requires oiling.

Unlike the conventional models, the oiling mechanism inside the frame has been eliminated. As a result, oil does not leak from the needle bar, presser bar or spreader shaft.

Dry-head technology has materialized a frame which does not need oiling.

The needle bar mechanism and spreader mechanism have been applied with a special surface treatment. JUKI’s unique special grease is used for lubrication. Grease-filled bearings have been adopted for the crank rod. These allow the machine’s frame mechanism to demonstrate outstanding durability without being oiled.

Environmental consciousness

Since oil stains on sewing products are reduced, the quantity of the use of stain remover generally used in sewing plants can be reduced.

Dichlorofluoroethane (HCFC-141), which is generally used in oil stain cleaning fluid, is included in those chemicals which need to be reduced, as it is a substances that can harm the ozone layer.

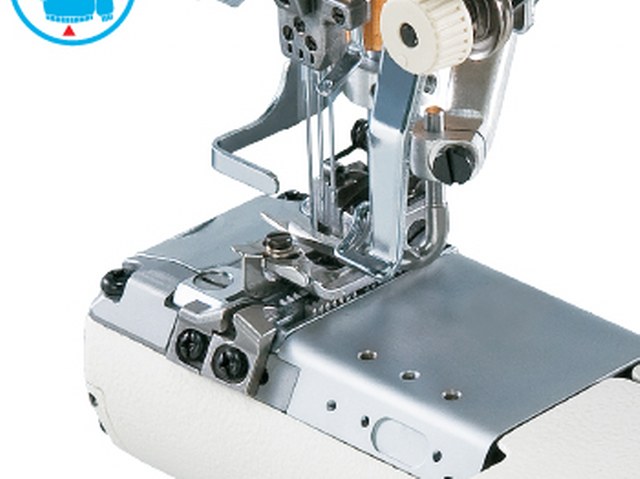

The sewing machine has been designed to achieve ease of use, placing the highest priority on easy handling and placement of the material on the sewing machine

The distance from the needle entry to the top end of the cylinder bed has been reduced to 36 mm, thereby facilitating the sewing and handling of the sharp curves of the armholes of children’s wear.

The cylinder length from its top end to the root has been increased to 65 mm, thereby ensuring easier sewing of the long sleeve cuffs of sweat shirts.

Since the top end of the cylinder bed has been cut aslant, placement/removal of the material on/from the sewing machine is carried out with ease.

The front cover has been tilted and shifted to the right. As a result, the distance from the machine arm to the needle has been widened to increase ease of work.

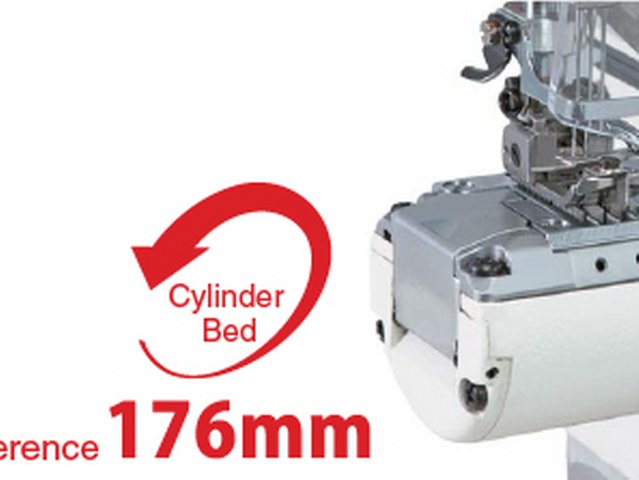

Outer circumference of the cylinder section is 176 mm!! *

The outer circumference of the cylinder section has been reduced to 176 mm. This al lows the sewing machine to easi sew conventional hard-to-sew small-in-diameter tubular parts such as the sleeve cuffs of sportswear and ladies’ cut-and-sewn wear and the necklines of children’s wear.

U10 Universal type (basic type)

The machine can be used for the hemming process of the sleeves and bottoms of T-shirts and for the covering process for sportswear and knitwear. It is a basic one which can be used for a broader range of processes independently.

The sewing machine supports hemming and covering (single-side bent and flattening) by the use of the guide supplied with the unit.

Differential-feed micro-adjustment mechanism

It is possible to finely adjust the differential feed amount to a best-suited value for the material to be used. The differential feed ratio is constant even if the stitch length is changed.

Micro-lifter mechanism

Elastic material or delicate material can be sewn with the presser foot kept slightly raised. This effectively helps reduce the degree of slippage, warpage and damage of the material.

The looper thread twining prevention mechanism

In the case of looper thread breakage, the looper thread twining prevention mechanism is activated to trim the looper thread before the thread twines on the looper thread cam. In addition, the looper thread cam, which has been incorporated in the sewing machine, has been changed so that it is mounted outside of the sewing machine.

All of the sewing machines with a thread trimmer are provided with a direct-drive motor.

The direct-drive motor system has been adopted by all of the sewing machines with a thread trimmer. As a result, the sewing machine starts up swiftly and promises increased stop accuracy, thereby demonstrating improved responsiveness. In addition, the machine is no longer provided with a V-belt. This means that the adoption of the direct-drive motor is also effective in the elimination of belt shavings. Power is directly transmitted from the motor to the sewing machine, thereby contributing to reduced power consumption. (This sewing machine reduces power consumption by 29% as compared with the conventional models.)

The actual product may differ from the product shown in the photo, depending on the subclass of the device

Technical specification for download: Click here

| Coverstitch machine for applications: | universal |

| Automatic needle positioning: | yes |

| Automatic thread trimming: | yes |

| Automatic foot lifter: | yes |

| Needle gauge of coverstitch machine: | 5,6 mm |

| Presser foot lift height: | 6 mm |

| Max. sewing speed: | 6000 s.p.m. |

| Built-in AC Servo motor: | yes |

| Needle system: | UY 128 GAS |

| Warranty period: | 12 months |