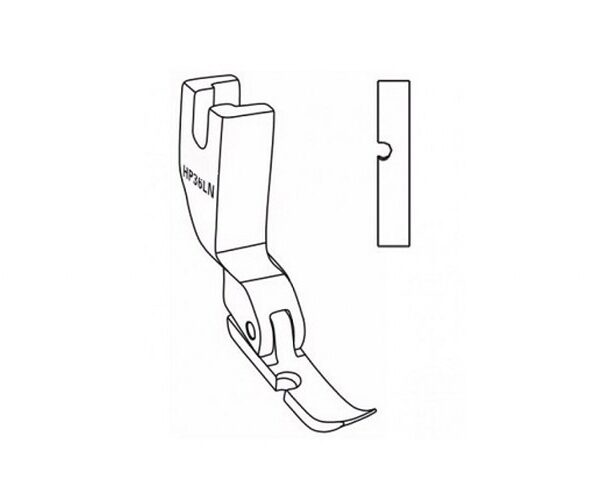

Description

Foot for industrial sewing machines – lockstitch machines with bottom feed.

Roller Width: 9.4mm

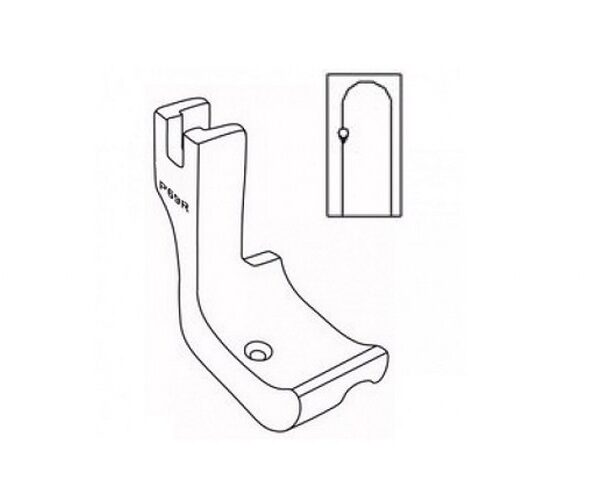

Plastic Roller Foot

Material:

The roller is made of plastic, often smooth or slightly textured

Application:

Suitable for lightweight and medium-weight materials

Ideal for slippery fabrics such as silk, satin, thin vinyl, or faux leather

Advantages:

Lightweight foot that reduces pressure on the material

Reduces friction on delicate fabrics

Limitations:

Less durable compared to metal options.

May wear out when used on hard or abrasive materials

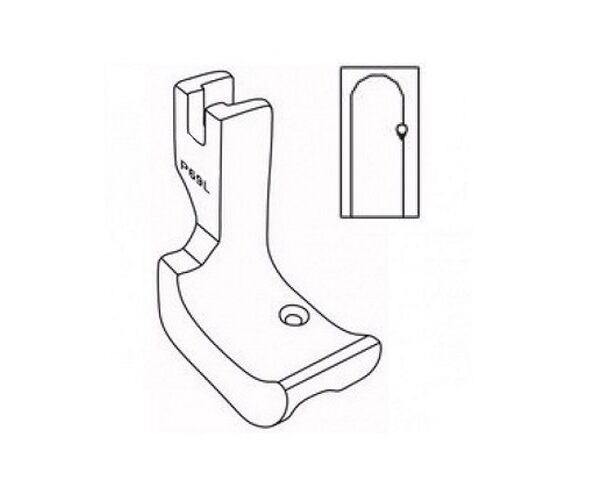

Rubber Roller Foot

Material:

The roller is coated with rubber for better grip

Application:

Designed for materials that are slippery or prone to deformation, such as vinyl, leather, plastic, and canvas

Excellent for materials with delicate surfaces, as the rubber prevents damage

Advantages:

Excellent grip on slippery and problematic materials

Reduces the risk of creases and marks on the fabric

Limitations:

Rubber may become less effective over time, especially with intensive use or when working with very hard materials

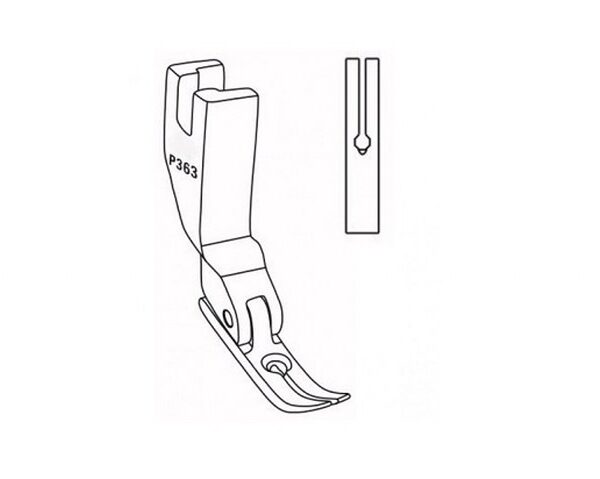

Steel Roller Foot

Material:

The roller is made of steel, grooved for a strong grip

Application:

Ideal for heavy and demanding materials such as thick leather, canvas, carpets, and other rough fabrics

Used in industrial sewing or projects requiring precision on hard materials

Advantages:

Durable and long-lasting, resistant to wear and tear

Allows smooth rolling and even material movement

Delivers the best results for thick layers of fabric

Limitations:

May leave marks on delicate materials

Heavier foot, which might affect sensitive fabrics

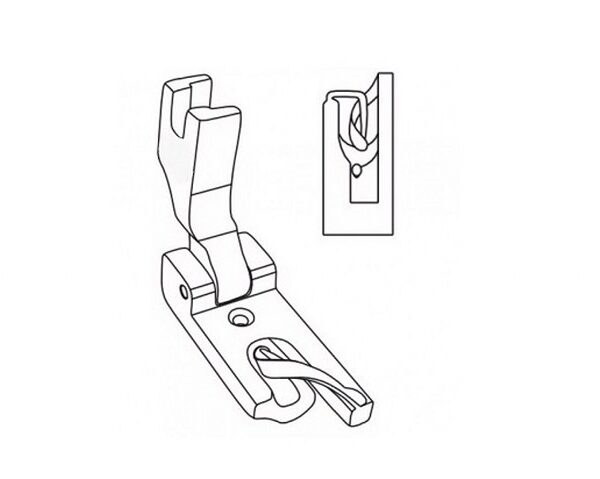

Knurled Roller Foot

Purpose:

Designed for sewing specific materials requiring better grip and less friction, such as leather, vinyl, plastic, or hard-to-feed materials

Application:

Features a knurled roller that enables smooth rolling over the material

Reduces dragging and wrinkling of the fabric.

Suitable for precise stitching on slippery or sticky materials

Advantages:

Improved material grip

Facilitates sewing circular and curved lines

Helps with thick or multilayer materials

Limitations:

May leave marks on delicate materials

Heavier foot, which could impact sensitive fabrics

Recommendations by Need:

Plastic Roller Foot – For sewing lightweight and slippery fabrics like silk or satin

Rubber Roller Foot – If better grip is needed for slippery or delicate materials like vinyl or faux leather

Steel Roller Foot – For working with thick materials such as leather, canvas, or carpets

Knurled Roller Foot – When precise sewing of challenging materials like vinyl, leather, or multilayer fabrics is required

| Characteristic | Plastic Roller Foot | Rubber Roller Foot | Steel Roller Foot | Knurled Roller Foot | Standard Presser Foot |

| Roller/Foot Material | Plastic | Rubber | Steel | Steel with knurled roller | Metal or plastic |

| Application | Lightweight and slippery fabrics | Slippery, delicate materials | Thick and heavy materials | Challenging materials like leather and vinyl | Universal for various materials |

| Durability | Low | Medium | High | High | High |

| Wear Resistance | Low | Medium | High | High | Medium |

| Fabric Grip | Minimal | High | Very high | Very high | Basic |

| Risk of Fabric Damage | Low | Low | Moderate (can leave marks on delicate fabrics) | Moderate (can leave marks on delicate fabrics) | Low |

| Foot Weight | Light | Medium-heavy | Heavy | Heavy | Medium |

| Ideal Material | Slippery fabrics like silk | Vinyl, plastic, delicate leather | Thick leather, heavy fabrics | Leather, vinyl, multilayer materials | Universal (cotton, canvas, etc.) |

| Price | Low | Moderate | High | Moderate | Low |

| Specific Advantages | Smooth gliding on slippery fabrics | Better grip without damaging materials | Durability for heavy-duty materials | Precision handling of challenging materials | Simple and versatile |